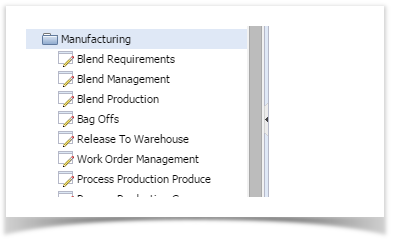

- Go to Manufacturing > Work Order Management

- Click on Work Order Management

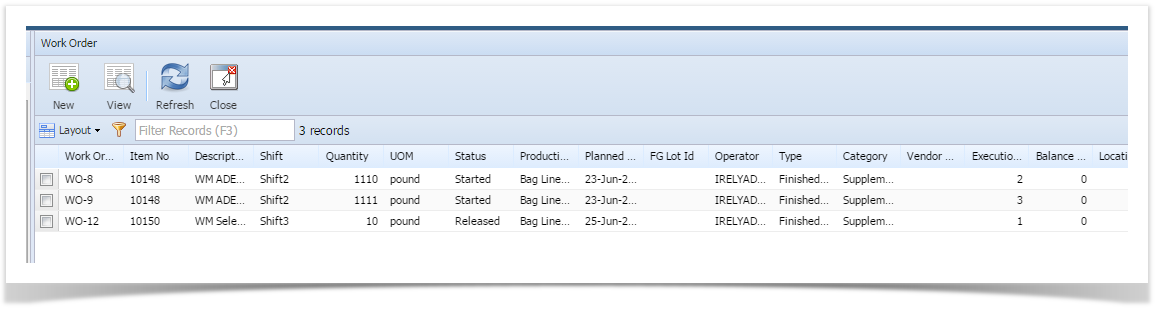

- The Manager will display as show below.

- If there is no work order available in the manager, then automatically New screen will open. You don't have to click on New button anymore in that case.

- If Work order exists, then you have to click on New to move on.

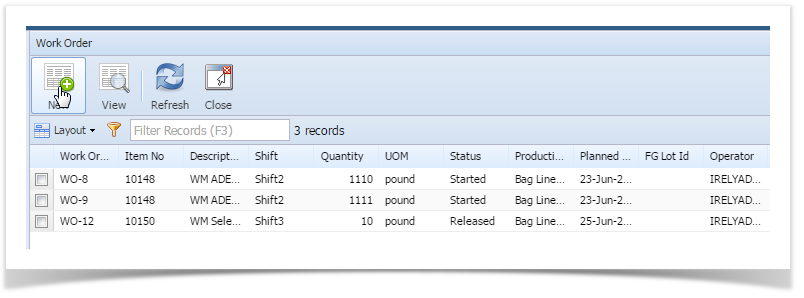

- Click on New button

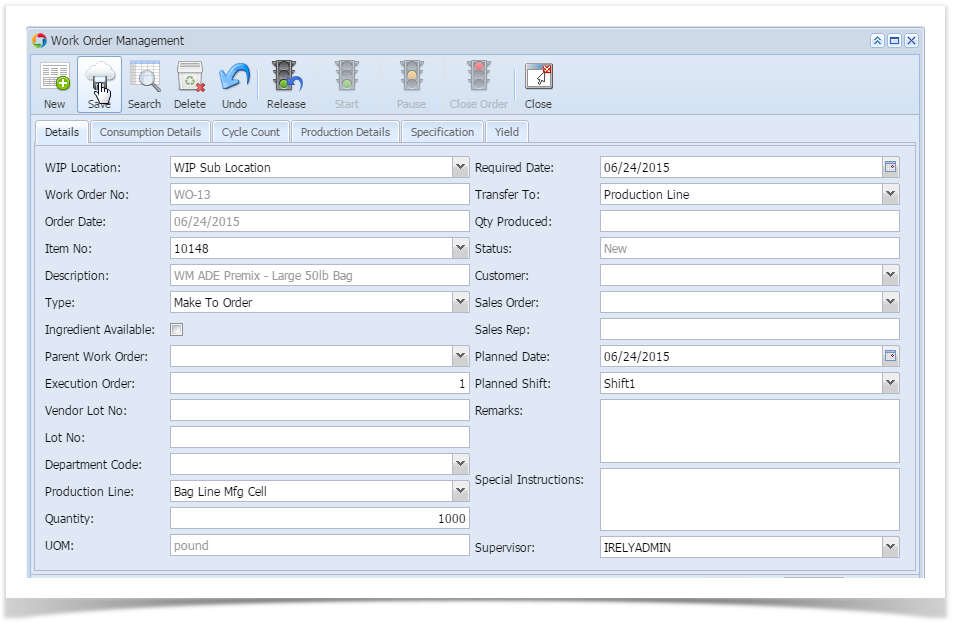

- New editor screen will open.

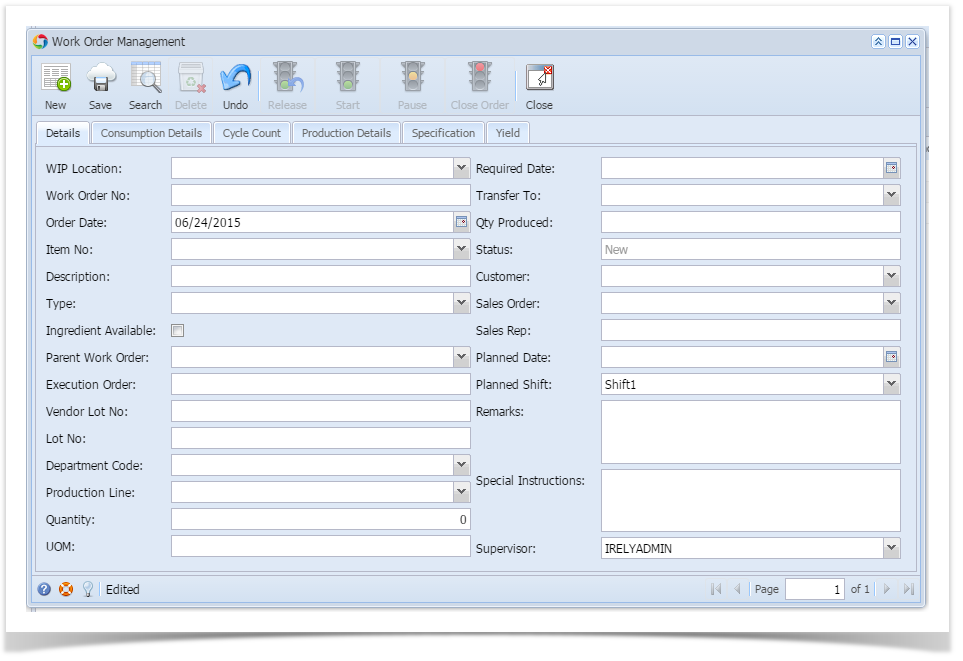

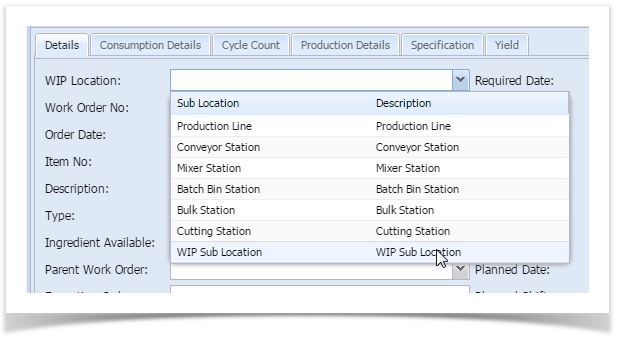

- Select a WIP Location

- Enter Work Order number. If you do not enter, the Work order number will auto-generate at the time of saving.

- Order date will by default show current date, if you wish you can change it.

- Enter other mandatory fields like Type, Production Line, Quantity, Required Date, Transfer To, Planned Date

- Click on Save

- Lot No is not mandatory field here. If you have the finished good lot ID ready, you can enter here. Else, the lot ID will auto-generate at the time of production.

- Close the Details screen

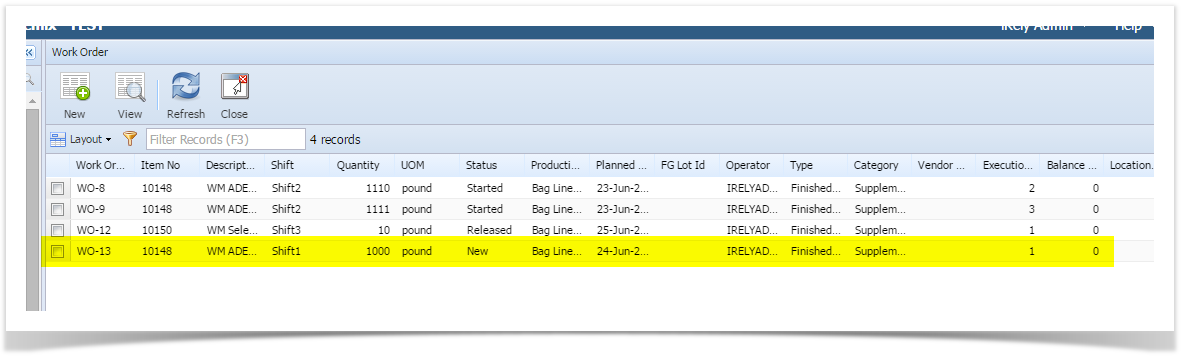

- You can now see the newly created work order in the manager.

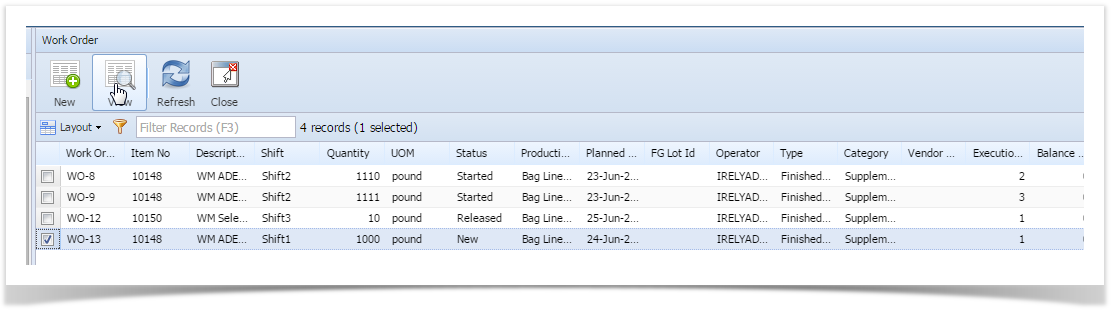

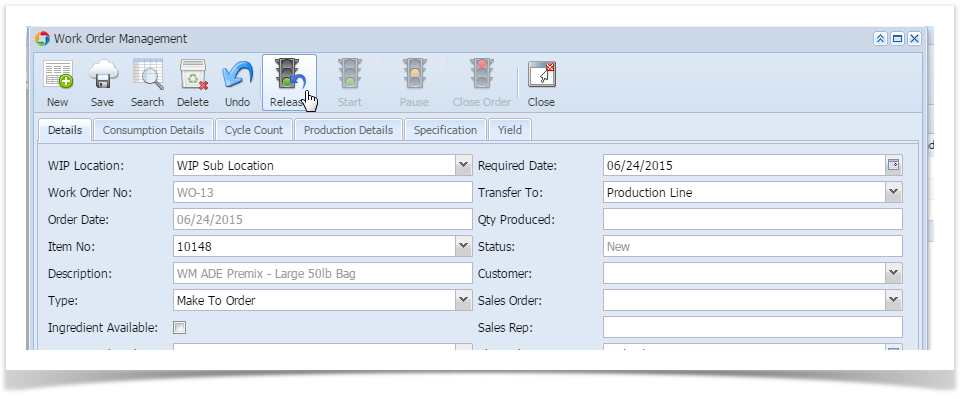

- After the work order is created, if you wish to release it, then kindly open the work order detail.

Note: Once you release, you cannot delete the Work order. You then need to close the Work order. - Once the Work order detail opens, click on Release button.

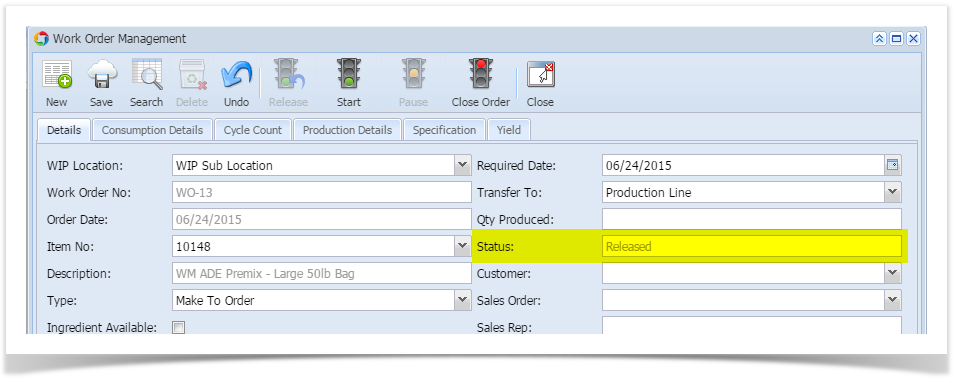

- Status of the work order will be "Released"

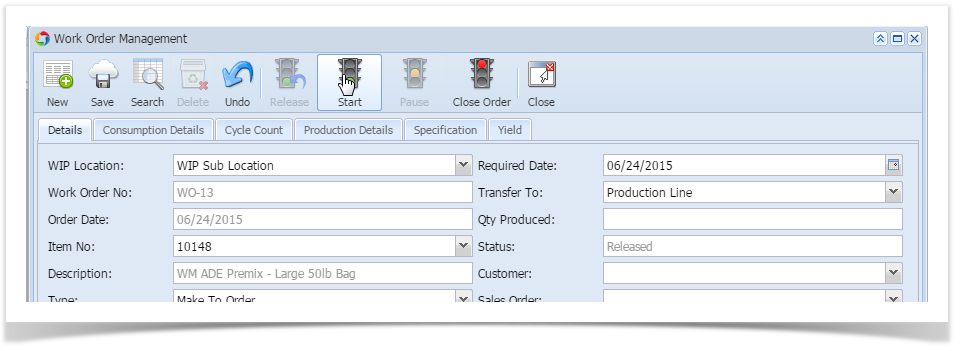

- Now, the Start button will be enabled. This will help you start the Work order, so that you can start consuming raw materials and produce finished good lots.

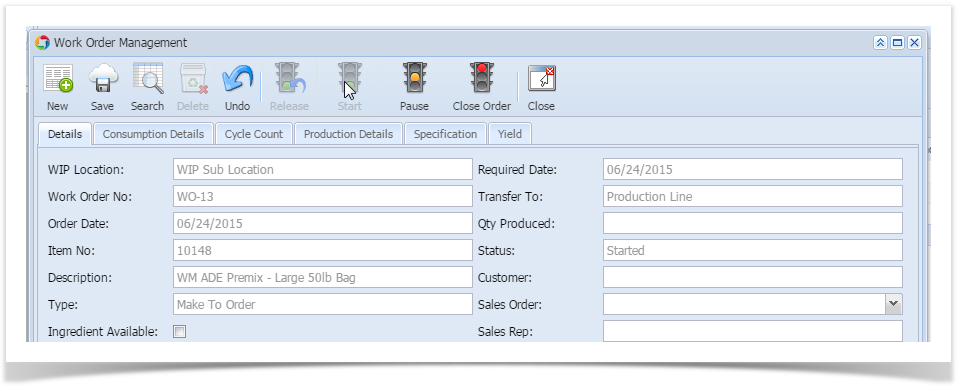

- Once you click on Start, the status of the Work order will be "Started"

Overview

Content Tools

1 Comment

Sabyasachi Mohanty

KR: FYI

How do I create, release and start a Work Order?