Page History

2. Recipe :

There should be an active recipe available for the work order item.

You can create a new recipe here.

3. Pack Type :

Pack Type used in the work order should be available in Pack Types maintenance .

4. Manufacturing Cell :

Manufacturing cell used in the work order should be available and also pack type should be associated with it.

5. Machines :

Machines used for the work order should be available and also pack type should be associated with it.

6. Production Calendar:

Active calendar should be available for the manufacturing cell which is used in the work order.

7. Item Configurations :

Manufacturing cell has to be associated with the work order item in item maintenance.

Pack Type should be mapped with the work order item

8. Company Locations :

Work order item category should be associated with the manufacturing cell in company locations maintenance.

9. Process and machine map :

Machines required for the work order should be associated with the process in Manufacturing Process maintenance.

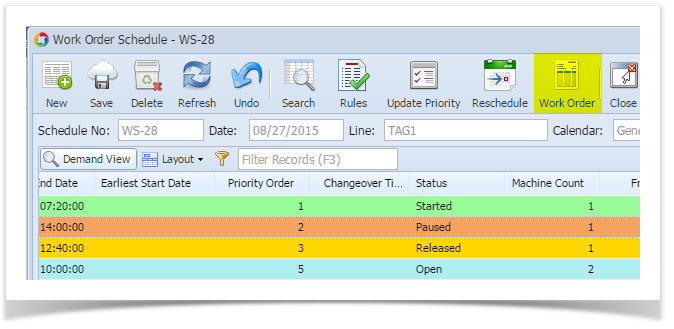

- Work Order Schedule screen allows user to schedule work orders. Schedule considers available machines and shifts for the dates mentioned in work orders. User can change the priority for the work orders and reschedule based on their requirement.

- Work orders that are created for specific production lines in ERP based on the forecast and sales order populate in iMake for scheduling

- User can manage the work order schedule in this screen

- User can configure the calendar which will have holidays, shifts and available machines for each day in production lines

- The calendar information is applied while scheduling the work orders

- User can view the work order schedule and available machines for the production line based on the calendar setup

- User can release the work orders for production, prioritize the production schedule for the work orders

- User can freeze/unlock work orders as per requirement. No operation is allowed on the frozen work orders

- Work Order Schedule window can be opened by either clicking on NEW button or by opening an existing schedule from schedule screen:

Work Orders Scheduling:

- Work orders will be listed by selecting the schedule number.

- Each work order will have the following information

...

- The work orders are displayed in sorted order based on "Priority Order"

- The Expected Date, Earliest Start Date or Priority Order Below columns can be changed or modified as required:

- Quantity

- Expected Date

- Earliest Start Date

- Priority Order

- Machine count

- Comments

- Additional Comments

- All the new work orders have status "NEW"

- User will have to change the status of a "NEW" work order to "OPEN" in order to schedule

- Once the work order is open, it can be released to allow production

- User can freeze/unlock any work order till the work order is started in production

- User can change the line of the work order

- User can close any work order as required

- After making changes in work order or priority, the work orders should be re-scheduled

- The work orders are color coded based on status. This color code can be defined as required

| Button Name | Function |

|---|---|

| To create a New Schedule | |

| To save the schedule details | |

| To delete the schedule | |

| To refresh the screen to get the latest data | |

| To rollback revert the changes made by the user | |

| To open an existing schedule from the Work Order Schedule screen | |

| To apply production schedule rules for the schedule | |

| To update work orders priority | |

| To reschedule work orders | |

| To open Work Order Editor details screen from work order schedule screen | |

| To close Work Order Schedule screen | |

...

Scheduling Features:

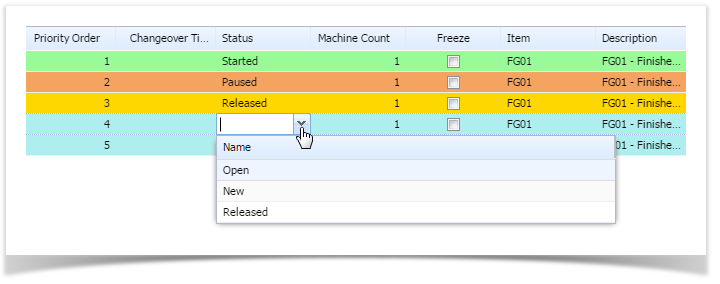

Change status:

User can change the status of the work orders using the Status column as shown in the below screenshot:

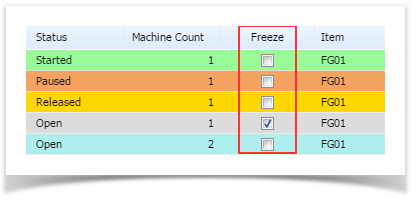

Freeze/Unlock Work Order:

User normally freezes the work order so that the work orders will not be allowed to change the due date, production line, etc

Work orders with "Open" status will only be allowed to "Freeze"

- Select the work order

- Check the checkbox under Freeze column to freeze the OPEN order

- Uncheck the checkbox to unlock the frozen work order

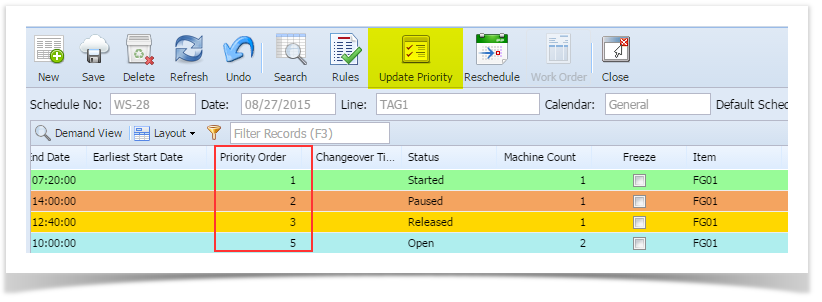

Update Priority Order:

User can either enter the priority order manually under Priority Order column (or)

This button is used to update the priority order of the work orders in sequence based on the work order status:

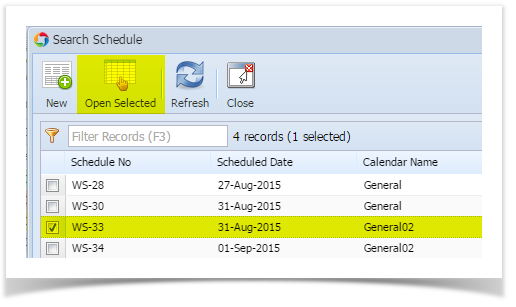

Search Button:

This option is used to open an existing schedule from the Work order schedule screen

- Click on Search button

- Select the schedule

- Click on Open Selected

Work Order button:

This button is used to edit or view the work order

- Select the work order

- Click on Work Order button

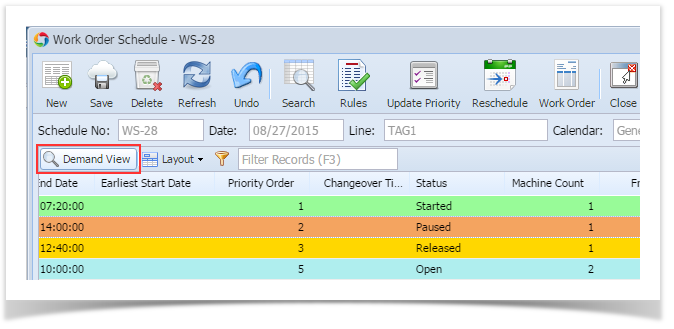

Demand View button:

To open demand view window for the selected work order

- Select the work order

- Click on Demand View button

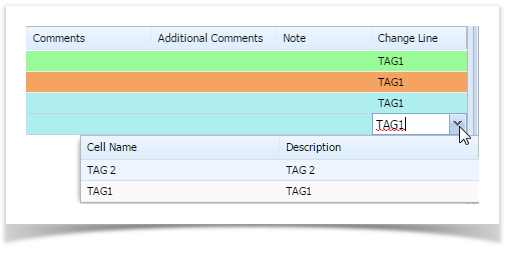

Change Line:

To change the production line of a work order with OPEN status

- Click on the Change Line dropdown of the work order

- It displays all the Production lines to which work order can be changed.

- User can select the New Line