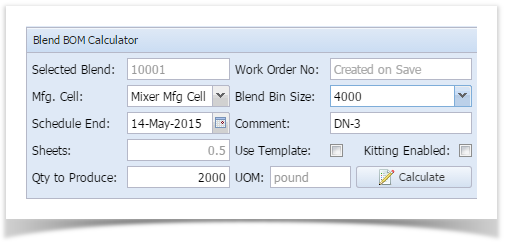

- Following is the sample BOM Calculator section in Blend Management screen

The user will setup the required parameters in this section as below to calculate required BOM for a blend sheet

Sl.no Data Description 1 Mfg. Cell All available Manufacturing Cells for the blend will be listed. The user will select the

Manufacturing Cell for which the blend sheet(s) will be created

2 Due Date Blend Sheet Due Date 3 Blend Bin Size All available blenders within the blend line will be listed The user will select the

blender with which the blend sheet(s) need to be created

4 Qty to produce Quantity to produce in each blend sheet

Note: This quantity will be less than or equal to Blend Bin Size

5 Comment Any user comment regarding the blend sheet will be entered in this - No. of blend sheets to be created ("# of Sheet" data)

a. "# of Sheet" will be by default 1

b. When the blend sheet is saved, "# of Sheet" should be 1 as only single blend sheet can be saved

c. When the blend sheet(s) are released, "# of Sheet" can be 1 or multiple, Make will release maximum possible blend sheets with the available selected blend sheet lots quantity - The user will click on "Calculate" button to display the required BOM in "Blend Input Material" section

- "Work Order No." will be generated by iMake and displayed when the blend sheet is saved

- Blend Sheet Template creation

a. When the blend sheet is saved or released, the user will check the "Use Template" check box to create a blend sheet template

b. The blend sheet template will have the work order number with which the template was created - Kitting Enabled

a. When this option is disabled, once the blend sheet is released, the blend sheet directly will be available for blend production without waiting for blend kit creation and transfer

b. When this option is enabled, the blend sheet will have to undergo kitting process before appearing in blend production

Overview

Content Tools