- The user creates blend requirements for required blend quantity based on the FG work orders schedules.

- Each blend requirement will have due date within which the blend quantity needs to be produced.

- In Make, a blend requirement can be created with or without providing the source information.

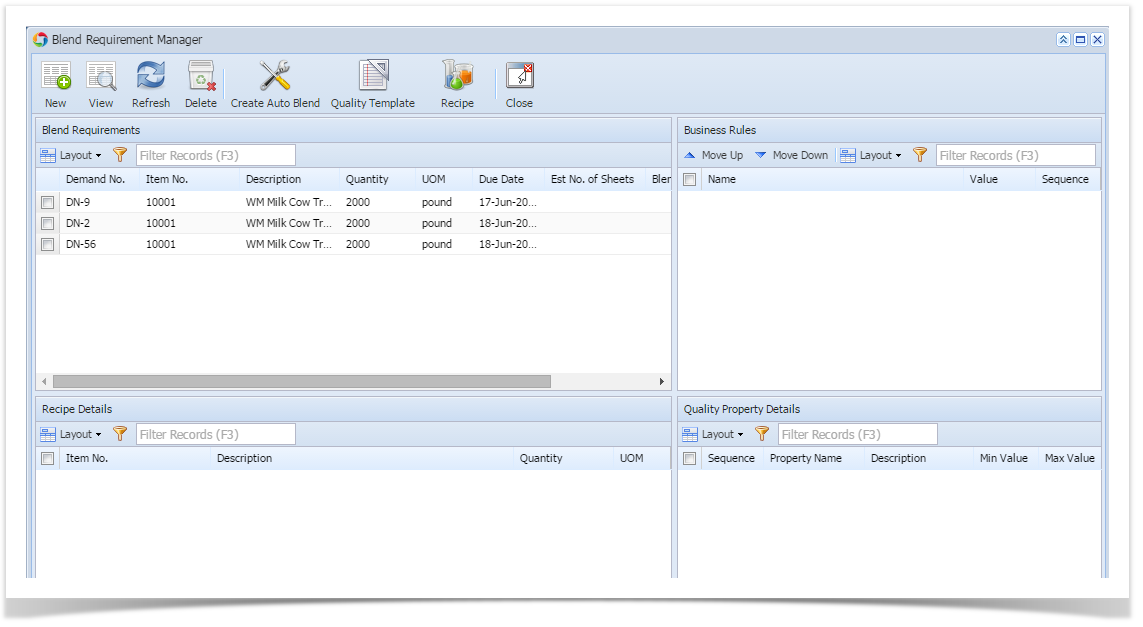

- Accessing Blend Requirement manager screen

Click on "Manufacturing --> Blend Requirement" as shown below - Blend Requirement manager screen has following sections.

> Blend Requirements: Displays all the created demand numbers.

> Recipe Details: Lists all the input items of select demand number.

> Business Rules: This will be applicable for MPTC customers.

> Quality Property Details: Displays Quality parameters. - Blend Requirement has following toolbars.

> New button

> View button.

> Refresh button.

> Delete button.

> Create Auto Blend button.

> Quality Template button.

> Recipe button.

> Close button. - Blend Requirement Manager

> New Blend Requirement will be created using the below screen by clicking "New" button in Blend Requirement manager screen

> Existing Blend Requirement can be viewed by clicking "View" button and the same requirement can be edited and saved

> Existing Blend Requirement can be viewed by clicking "View" button and the same requirement can be closed in the Blend Requirement Detail screen - Click on "Check MRP" to check the inventory of the selected blend item and the availability of required raw material lots quantity for production

Overview

Content Tools