Overview:

- This feature will be useful to capture the quality detail of the lot

- Typically the quality is captured for the material in the following control points:

Raw Tea: At the time of contract, shipment and while receiving, Blend, FG: Production and Shipment - The user can configure different control points to capture the quality of the lots like Offer Sample, Approval Sample, Receiving, Production, Shipment

- The lots for which the quality capture process is essential will be in "QUARANTINE" status. The "Quality Sample" window has an option to "Approve" the lot so that the status of the lot will be changed to "ACTIVE"

- This window will display the properties configured as "Quality Template" which is relevant for the material

- This window records the user and time of the quality approval of the lot

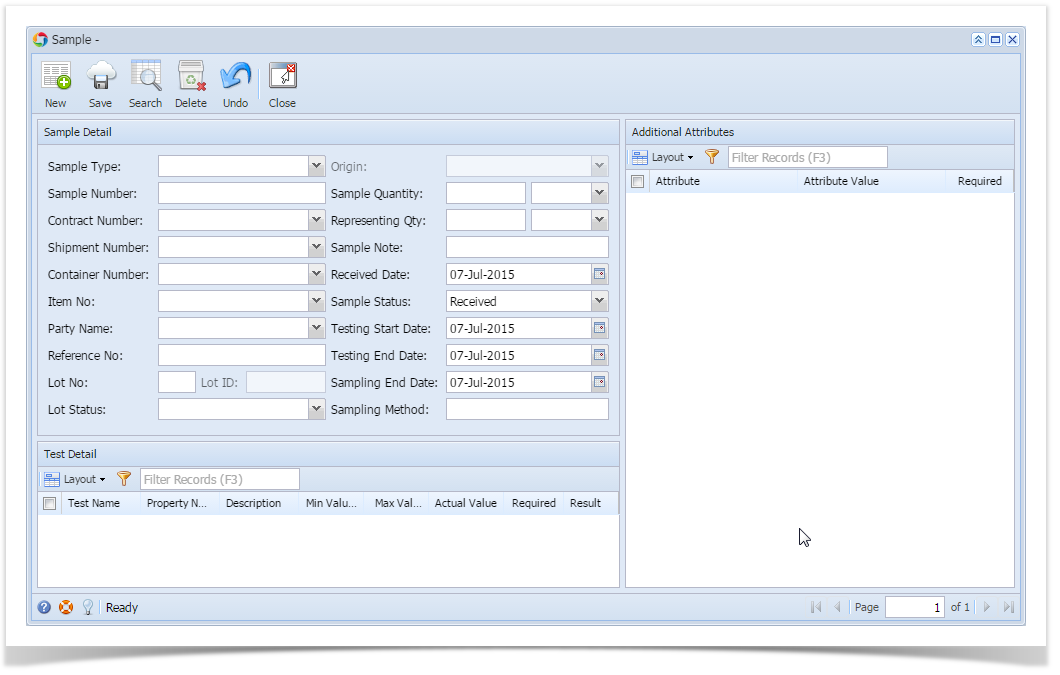

- "Quality Sample" screen can be opened by navigating to Quality - Quality Sample.

Quality Sample screen has the following three sections

- Sample Detail

- Test Detail

- Additional Attributes

Sample Detail has the following fields.

| Field | Description |

|---|---|

| Sample Type | Sample Type configured against the control points |

| Sample Number | Sample number as generated by automatically |

| Contract Number | Contract number of procurement of material |

| Shipment Number | Shipment number of material procurement |

| Container Number | Container number of material procurement |

| Item No | mandatory field. if contract is selected will show items from the contract. if screen is opened from inventory view/lot view should populate the item that is selected. |

| Party Name | if contract is selected show populate vendor associated with contract |

| Reference No | Optional |

| Lot No | Optional |

| Lot ID | Optional if sample type is offer sample/pre-shipment sample Mandatory if sample type is receipt sample/inventory sample/production sample |

| Lot Status | Status that should be assigned to lot after approval/rejection. Mandatory at the time of approval/rejection if sample type is receipt sample/inventory sample/production sample |

| Origin | Origin Country of the raw material |

| Sample Quantity, UOM | The amount of material taken as sample |

| Representing Qty | Total quantity being represented by the sample |

| Sample Note | Optional |

| Received Date | Sample received date |

| Sample Status | User can select a secondary status |

| Testing Start Date | Optional |

| Testing End Date | Optional |

| Sampling End Date | Optional |

| Sampling Method | Optional |

Test Detail has following fields

Each line of the test detail is of a Property and Test configured under quality template

| Field | Description |

|---|---|

| Test Name, Property Name, Description | Property name and relevant details |

| Min & Max Value | Expected Minimum and Maximum Range |

| Actual Value | Actual value to be entered by the user; |

| Required | Based on property configuration |

| Result | Result for the actual value compared to the expected range (Passed or Failed) |

| UOM | Displays the Unit of Measurement |

| Low & High Value | Allowed Low and High Range |

| Sequence No | Displays sequence no |

| Replications | No. of times the test to be conducted |

| Final | Displays the final result |

| Comment | Optional |

| Cr./Dr. (Price %) | |

| Cr./Dr. (Qty) | |

| Formula | Displays the configured formula |

| List | "List Name" is populated for user selection when the property data type is "List" |

Additional Attributes has following fields.

| Fields | Description |

|---|---|

| Attribute | Attribute associated with sample type |

| Attribute Value | Value for attribute |

| Required | As configured in Sample type |

Following is the screen shot of "Quality Sample" screen

Mandatory fields for each Control points

- Offer Sample

- Approval Sample

- Inspection

- Inventory Quality

- Receipt Sample

- Production

- Production Computed

- Shipping

For all the above control points following are mandatory fields- Item No

- Sample Qty and UOM

- Representing Qty and UOM

Overview

Content Tools